Concrete Pump Safety Manual

Safety Considerations PUMP SAFETY Checking for Wear Pumping performance, as well as safe operation of the pumping system, may be affected by worn couplings or gaskets, which may let air into the line or allow grout to escape. Couplings: Typically wear on the surface that comes into contact with the pipe. Gaskets: Need to be cleaned if they have concrete remaining in the cavity and should be replaced if the center lip is worn out. Valves: Routinely inspect for wear and proper settings. Pipeline: The most accurate way to inspect for worn pipeline is with a gauge specifically designed to measure the thickness of steel pipe. In addition, the pipe ends must be inspected for cleanliness, wear and compatibility. Since pipe joints can pose a serious hazard if the ends and couplings don’t match, compatibility between American, European and different manufacturers must be ensured.

Securing the System Improper tie-down is one of the most common causes of accidents when pumping concrete. Support brackets, designed to hold the pipeline in either a horizontal or vertical position, should be spaced every 10 to 15 feet in order to take weight off of the coupling joint, and to transfer the pumping torque to a building column or beam. Cleaning the System If done improperly, cleaning the system after the daily pumping job can be very hazardous. Water should be used for cleaning whenever possible and practical, since it is the best and safest cleaning method available. If cleaning with compressed air, remember that the pressure builds up, and may remain in the line even after the supply is shut off. A bleed-off valve should always be installed on the system when using compressed air.

Remember that this built-up pressure can be of sufficient force to propel a clean-out ball through the open end with enough force to penetrate a concrete block wall. Therefore, whether using water or air pressure, install an end cap and a catcher to prevent injury to workers or damage to property. PROPER TRUCK POSITIONING The primary concern when utilizing a pump truck during a pumped concrete pour is safely positioning the truck where the boom can reach the concrete placement site.

The key word here is 'safely.' Improperly positioned, a pump truck can cause death or serious injury, making a nightmare out of what may have appeared to be a standard, 'every day' pour.

The pumping crew can only utilize the pump truck and boom when the conditions are entirely safe. Placing the Boom Prior to extending the pump truck boom on a new job site, check for the following:.

Power Lines. Excavations.

Other obstructions Power Lines: The truck boom, chassis, remote-control cable, and steel-braided end hose are great conductors of electricity. And with its high water content, the concrete itself can become a deathly electric conduit if any part of the pump machinery comes in contact with power lines. This is why more concrete pump operators die from electrocution than any other job-related cause.

And even the rubber boots or rubber-soled work boots worn by concrete workers won’t protect them from the 8,000 volts most residential power lines carry if that worker is in contact with any part of the equipment that touches a power line. Half of all accidents involving booms and power lines happen when the machine is being folded, unfolded or removed. This is why OSHA recommends placing a full-time spotter in position to keep an eye on the boom if it’s at all possible to inadvertently hit an electric wire. The American Concrete Pumping Association requires that the boom tip and any other section of the boom be at least 17 feet (5 meters) from power lines. Depth perception when judging far away objects is seldom reliable, and should be avoided when operators are placing their booms. Instead:.

Operators should use a radio or cable remote control after positioning themselves so they can accurately judge the distance between the boom and the wires. The best place to judge that distance is perpendicular to the boom, between the placing area and the power wires. Employ a spotter using a two-way radio or hand signals to assist the operator in maneuvering the boom in the event the operator can’t leave the pump.

Free Safety Manual Download

If the operator is required to set up at the jobsite before daylight or after dark, a flashlight or spotlight should be used to check for power lines. However, always err on the safe side, and save unfolding the boom until daylight if there is any question as to the existence of power lines. Excavations:Remember the 'one-to-one' rule when pumping concrete near an excavation or land that falls off steeply from the pump: For every foot of depth, position the pump at least one foot back from the edge.

Pumps can be placed closer to the edge of a slope than to a vertical drop-off. For instance, on a one-to-one slope, the pump often does not require much of a setback and can often be placed at the top of the slope. When pumping into an excavation, take into consideration the fact that most boom pumps have a much higher upward reach than downward.

A boom pump that can reach 100 feet high may have only about half that reach downward. Other Obstructions:Obstructions on the job site other than power lines may cause problems, as well.

Pay careful attention to objects such as cranes, scaffolding or buildings. Make sure the boom’s length and articulation are right for the job. Even though a shorter boom may be able to place the concrete correctly, it may be too short to clear other obstructions. Stabilizing the Pump Truck Wood and aluminum pads and layers of 4 x 4- or 4 x 6-inch boards (called cribbing) are often used under the pump trucks outriggers to spread out its load. This requires determining the load bearing capacity not only of the soil, but of the cribbing, as well.

Calculating Pressures on Ground Surfaces (mathematical): In order to stabilize the concrete pump truck, it must be determined if the proper support is being given for the type of surface the truck is mounted on. One way to do this is to calculate the pressure placed on the soil by each of the trucks outriggers by dividing the maximum force on the outrigger leg by the area of soil contact. The area of soil contact is either the area of the wood or aluminum pad, or the cribbing, if used, on each outrigger. The pressure from each outrigger must be less than the load bearing capacity of the soil. (See Table: Allowable Pressures for Various Surfaces, below) Calculating Pressures on Ground Surfaces (physical): Since operators often don't know the soils bearing capacity, a physical test is often used. This involves laying cribbing on a firm spot of ground and positioning the outriggers on them.

Fourth gear is provided by the overdrive unit (rear section) that contains an overdrive clutch, OD/direct clutch, overrun roller clutch, and planetary gear set. Chrysler 46rh transmission problems.

One at a time, the operator extends the boom out over each outrigger, checking to see if the cribbing sinks. If it does, it means the boom must be refolded, and a larger area of cribbing put in. Table of Allowable Pressures for Various Surfaces. Surface Pressure (PSI) Ground (soil) 22 Asphalt, min. 8 inches 29 Compressed crushed Stone 36 Clay/silt soil 43 Mixed granular soil 51 Firm compacted gravel 58-109 Brittle weathered rock 145 CHOOSING THE PROPER HOSE Hoses are manufactured for specific applications, and using the proper hose for the proper application is paramount for safety on the concrete pumping site. Here are a couple pointers:.

Hose designated as a discharge type should be used only at point of placement for discharge. Rule of thumb: Never use a discharge hose in less than a 24-inch radius. For boom truck applications, a specially reinforced hose is recommended. Rule of thumb: Never use a boom hose in less than a 30-inch radius. SAFETY 'DON'TS' FOR PUMP OPERATORS Carelessness in the field can cause accidents, no matter how many safety measures are built in to the equipment and procedures.

Keep these safety 'don’ts' in mind: Don't:. Open a coupling that is under pressure. Face an open discharge end of the pipeline.

Pick up a clogged hose that is under pressure. Climb on a hydraulic system to clean a clogged line.

Concrete pumping provides the fastest and most economical method for placing concrete on construction jobs. However, the process is not without danger and often presents numerous hazards. To prevent accidents on the job, these do’s and don’ts of concrete pumping should always be on your mind. Contractor Responsibilities Organization is the key to at the concrete pumping worksite. Consequently, the contractor in charge should be responsible for seeing that the proper equipment is ordered for the needs of the job. He or she is also responsible for identifying potential hazards and remedying dangerous situations to prevent accidents.

The (ACPA) recommends that all concrete pumping operators receive safety certification to prevent accidents and learn how to operate the equipment safely, so it is your duty to make sure that all your personnel is up to date on the latest training courses and certifications in order to prevent accidents from occurring. Preparing the Site Site preparation begins well before the pumping process. Be sure to remove all clutter and clear out some space for the pumping truck. Ideally, the space has already been leveled and is large enough to handle a pump using extended outriggers. Additionally, there should be enough space to handle a couple of mix trucks. Powerlines Power lines cause the most fatal accidents while pumping concrete. To prevent or reduce these types of accidents all personnel should receive electricity and power line safety training.

When a power line exists near the job site, a danger zone should be established and marked with cones. In addition, a spotter should be on hand at all times to warn an operator when the boom comes dangerously close to the designated danger zone. It is also recommended that a meeting is conducted to discuss how the pouring operation will be handled and safety methods for avoiding nearby power lines. According to ACPA, booms should never be used within 20 feet of power lines. Cribbing Adequate cribbing is essential to distribute the weight or balance of the cement load. Typically, pump manufacturers do supply some outrigger pads with their pumping equipment.

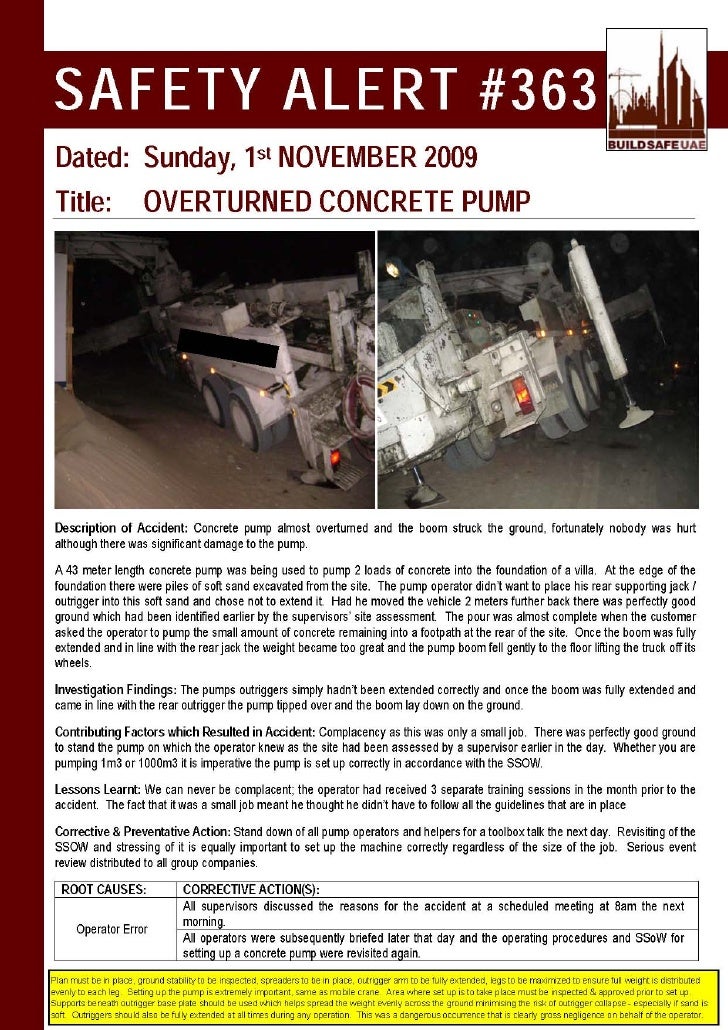

Contractors may also have an extra supply of steel plates or wood dunnage that can be used for additional cribbing when needed. Outriggers In addition to power line accidents, poor outrigging procedures can cause numerous accidents on construction work sites when pouring concrete.

Tip overs are predominately caused by using outriggers without sufficient cribbing, or the site surface has not been properly prepared to support the weight of an outrigger. Occasionally, an unknown underground void could be the cause of tip overs. The soil type can be a critical factor when it comes to keeping outriggers safe and steady. Each soil type can have a different load-bearing capacity. For example, replacing virgin ground with compacted gravel more than doubles the support capabilities.

In some situations, tip overs occur when outriggers have not been fully extended. Do’s of Concrete Pumping. Use trained and certified operators. Safety straps should be checked for wear and used on the tip hose and hanging attachments. Prepare the ground properly using outrigger pads. Operators should always wear the appropriate protective gear. Only use boom equipment that is working correctly and has had updated inspections.

Remove all personnel from the area when air is entering the placement system. Don’ts of Concrete Pumping. Never use a boom to replace the job of a crane. Don’t open a coupling when it is pressurized. Never climb on hydraulic systems for the purpose of cleaning clogged lines. Don’t stand in front of the discharge end of cement pipeline.

Never handle clogged hoses that are under pressure. Don’t operate or set up a concrete pump when it is dark. Make sure there are no workers near a discharge hose while it’s being primed.

Concrete Pumping Insurance Regardless of how carefully a concrete pumping job is planned, accidents can still happen. Before accepting any concrete pumping job, you should make sure you have concrete pump insurance in place to protect your company and employees. General Liability Coverage: Protects businesses against a variety of liability claims for property damage, bodily injury and personal injury. Concrete Pumping Insurance: Offers coverage for concrete pumpers rented including over-the-road liability, loss of income and extra expense, loss of rents, equipment in your care and more. Physical Damage & Auto Liability: Covers personal effects, towing and the physical damage of any rentals. Workers Compensation: Coverage to protect workers that may be injured on the job while pumping. Concrete pumping can be a dangerous job.

It is up to contractors to take safety precautions whenever possible. Jobs should always be carefully planned, and sites should be prepared properly before beginning work.

Using the proper safety equipment and resolving safety issues reduces the chances of concrete pumping accidents. Make sure you’re protected from any accident that may occur by working alongside the from Allied Insurance Brokers. With over 10 years of experience in the industry, the Allied team can help provide real solutions that work to protect your business from risks and build your bottom line. For more information on how Allied Insurance can help deliver bottom line solitons to your brand, contact us today!.Allied does not deem this blog entry as a complete and thorough listing or overview of the above topic, and does not recommend it be primarily relied on.

It only highlights some common issues and resolutions. For a thorough overview, please contact Allied’s Risk Engineering Division.